Unimat 09-4×8/4S Dynamic – track and turnout tamping unit

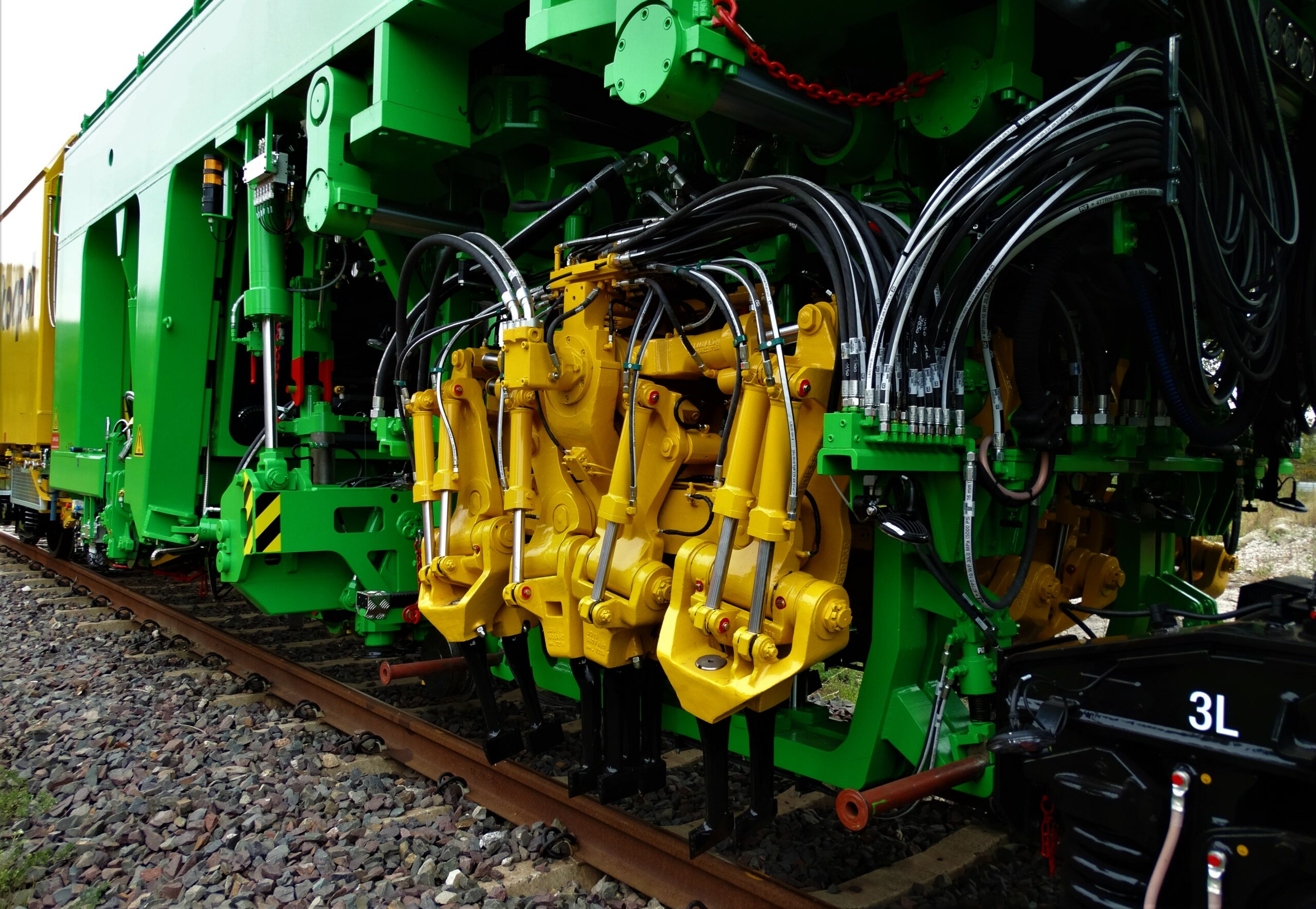

Unimat 09-4×8/4S Dynamic is a 10-axis universal tamping machine based on the operating principles of the latest Unimat 4S. The execution of track and turnout alignment works in vertical and horizontal planes with simultaneous stabilization of the track structure is combined in one universal machine. The Unimat carries out turnout maintenance according to the latest state-of-the-art technologies, such as the lifting of 3 rails without the need of ballast bed support and the tamping of 4 rails in order to repair diverging tracks. Also, by means of 32 universal tampers and 25 tilting tampers in continuous operations on turnout sections, the machine has gained increased capacity. In addition, it is capable of tamping 2 sleepers during track tamping.

The tamping machine is designed as a two-part vehicle, consisting of a main machine and a power carriage with stabiliser. The main machine is mounted on 2-axle bogies and consists of a front cab, a working cab for the tracks and a working cab for tamping the tracks and turnouts. It also has a suspension point for the frame on which the tamping and lifting unit is mounted. The integrated power and stabiliser carriage is also located on a 2-axle bogie and is connected to the tamping machine at the front by means of a connecting beam. It is equipped with buffers and a coupling at the end of the frame.

With a length of almost 43 m, Unimat 09-4×8/4S Dynamic is one of the longest self-propelled machines operating on Polish tracks. Despite its dimensions and its own weight of 189 t, the machine can move independently between worksites at speeds of up to 100 km/h.